BLC 4000 Ceiling air inlet (discontinued)

Horizontal ceiling inlet (discontinued)

Single and double Twin inlet shaft (discontinued)

Flash 3300 ventilation slide

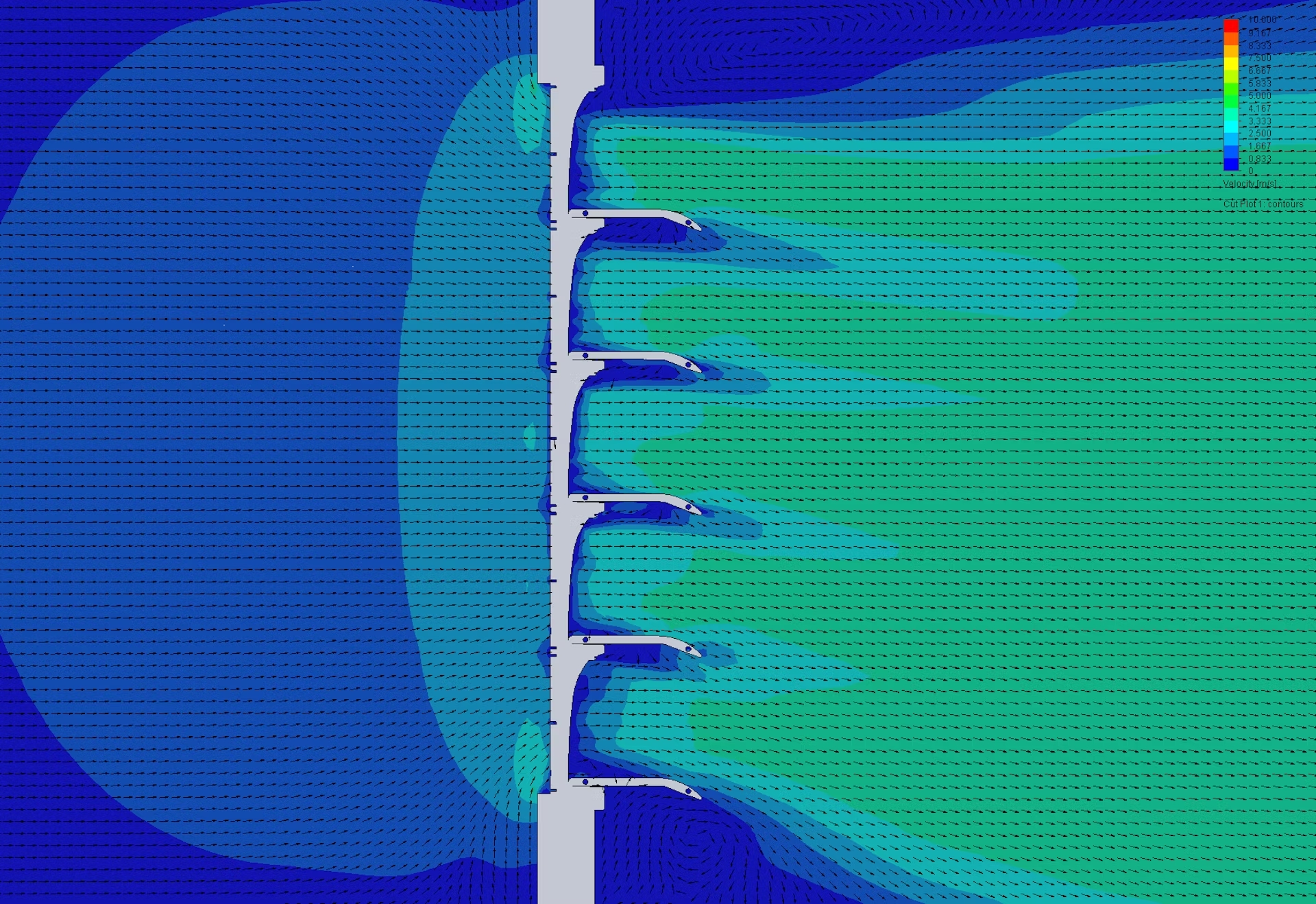

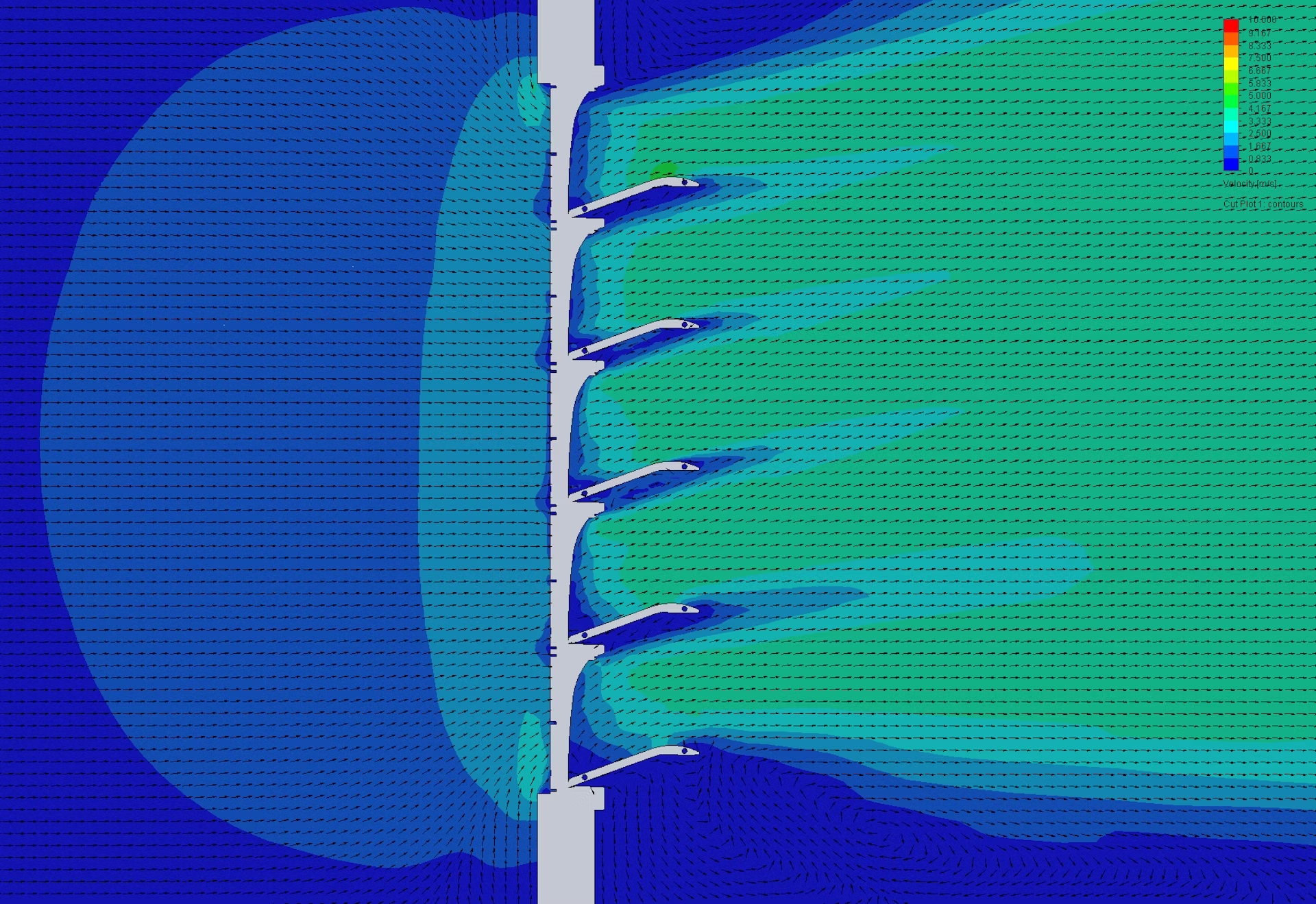

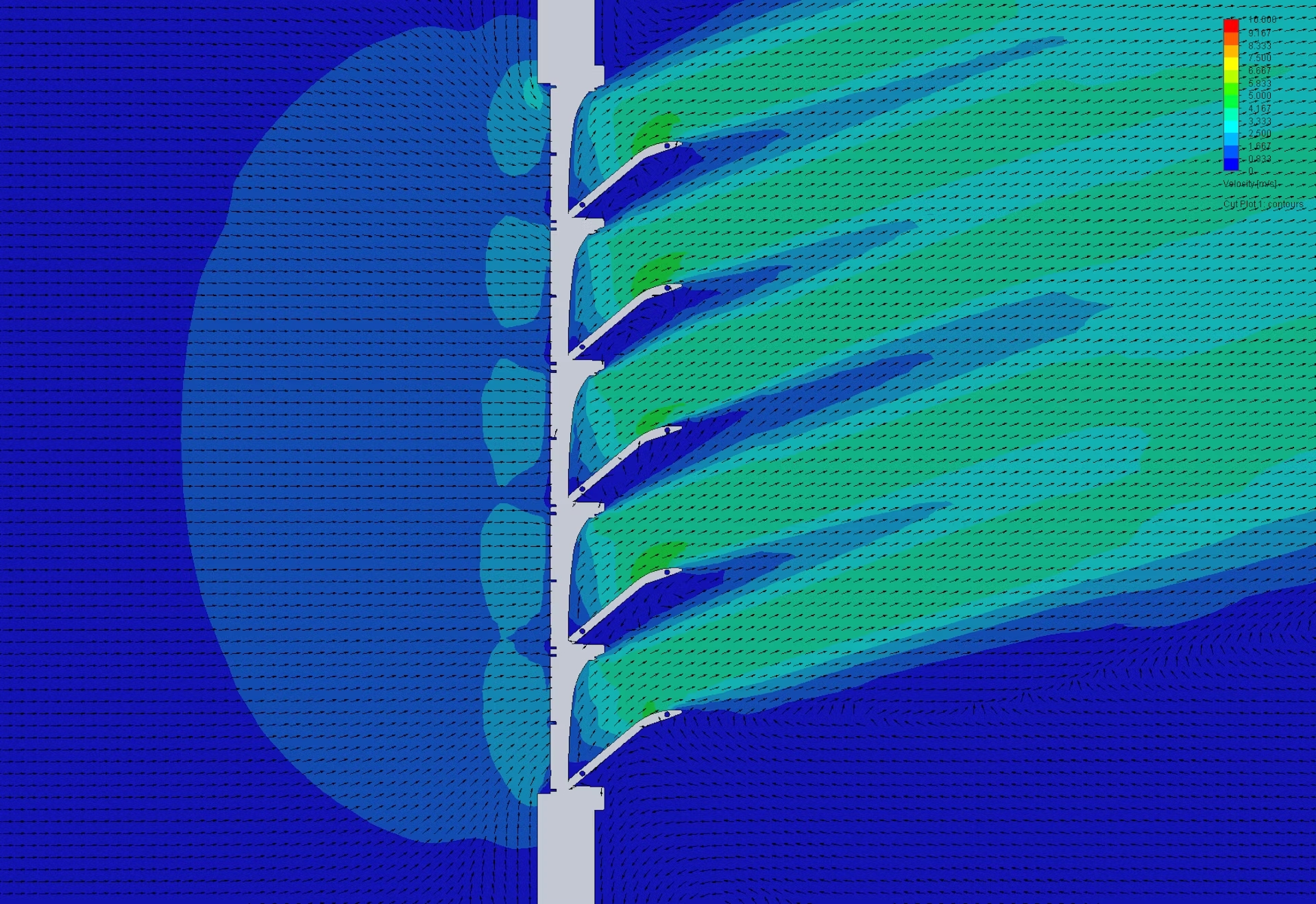

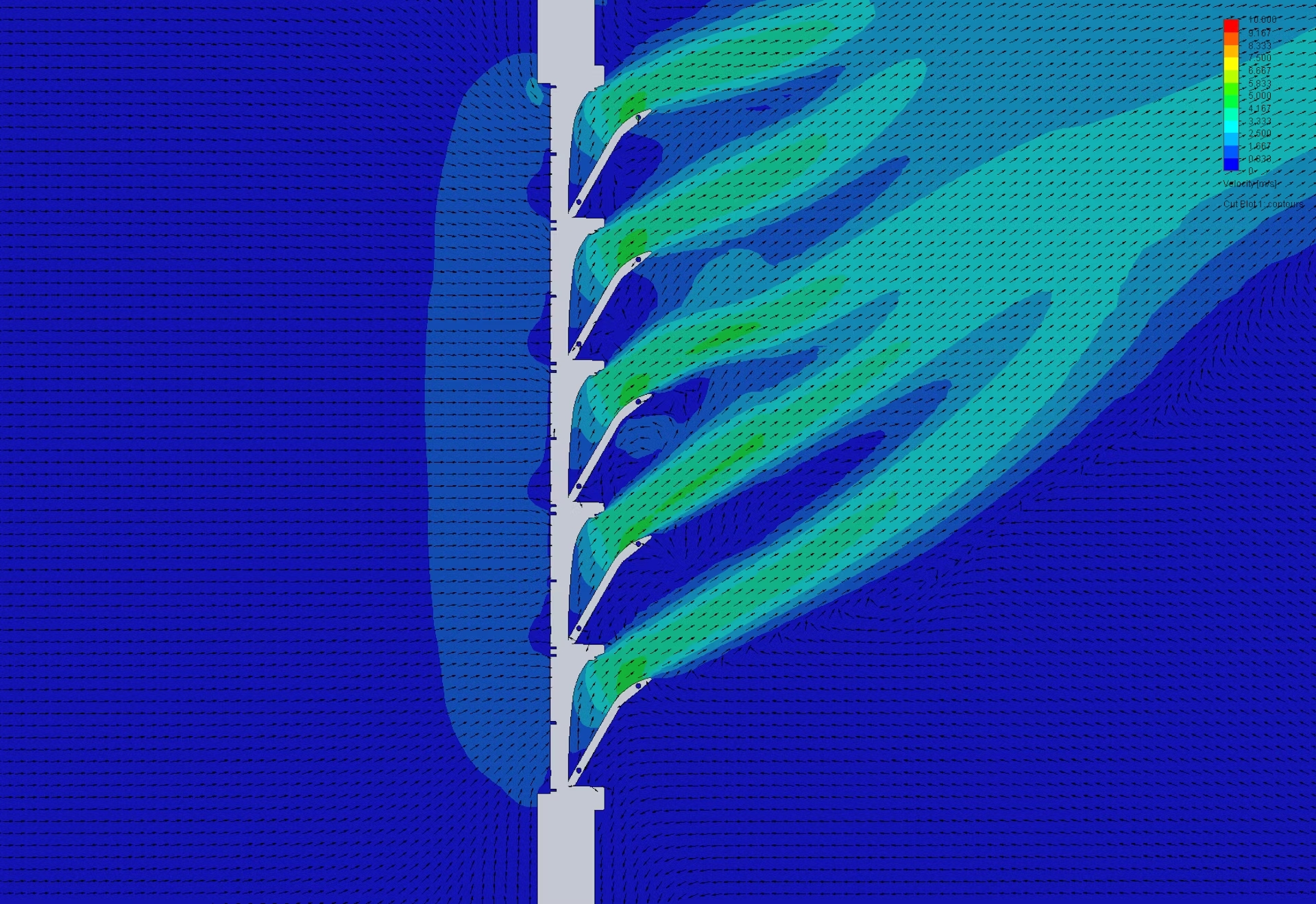

X-Stream wall inlet

BL 4500 wall inlet

BL 6200 wall inlet

Air Optimizer

Flash BP wall inlet (discontinued)

4-Seasons (discontinued)

Twin wall inlet (discontinued)